- Geared drive by toothed belt

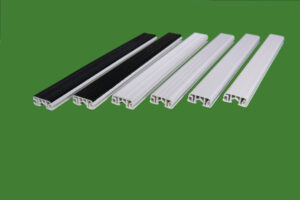

- Available with the lath surfaces:

- PKG2410: grooved

- PKG2410K: grooved with cross-ribbing

- PKG2410W: smoothed PVC grooved

- PKG2410WK: smoothed PVC with cross-ribbing

- PKG2410C: smoothed PVC conductible(black), antistatic

- PKG2410CK: smoothed PVC conductible(black), antistatic with cross-ribbing

- Full compatibility with the system available on the market with the following advantages:

- The tooth of the toothed belt is 1 mm higher. The interchangeability is not yet limited because of that. However the safety of the forced drive is much better – the danger of missing tooth is much lower!

- Damages due to laths which are working loose can be excluded because of a stable connection. A replaced lath must be destroyed. This disadvantage, however, can be considered to be irrelevant, since a replacement is normally only carried out in the case of damage. This leads to a higher operational reliability.

- The highest care and the highest quality conditions during the production of the laths always guarantee the same high quality of the lath surface.

- Belt connection through overlapping connections.

- There is the possibility to pull in fabric strips between the laths.

- End-caps are available to secure the strips and as gliders.