spiked lattices

Below you find our general product portfolio of spiked lattices.

The combination of different components used in the lattice depends on the type of machine, the material handled and the performance required.

Most spiked lattices got a continuous support which prevents the material from falling though the laths.

If you want to request a lattice our questionnaire supports to describe the required specifications and you can send your request directly to us.

We are able to produce all forms and dimensions of spiked lattices. If you don’t find your model below, contact us.

aluminium PAS2411

Application hopper feeder for thin fibers and mixing chambers

Advantages: Robust, lightweight, stable laths and pin position

Profile of laths: 24mm wide x 11mm high with hollow core

Material of laths: Aluminium

Belt: Transilon or toothed belts

Endless connection: overlapping, screwed nonpositive belt connection

Pins: Standard pins 3,35 mm diameter, lengths 35mm

Support: Polyester web strips between laths

aluminium PAS3020

Application: hopper feeder

Advantages: Robust, stable laths and pins, geared drive possible

Profile of laths: 30mm wide x 20mm high with hollow core

Material of laths: Aluminium

Belt: Polychrome, transilon or toothed belts

Endless Connection: overlapping, screwed belt connection

Pins: Standard pins 4mm diameter, length 35mm up to 60mm

Support: Polyester web strips between laths

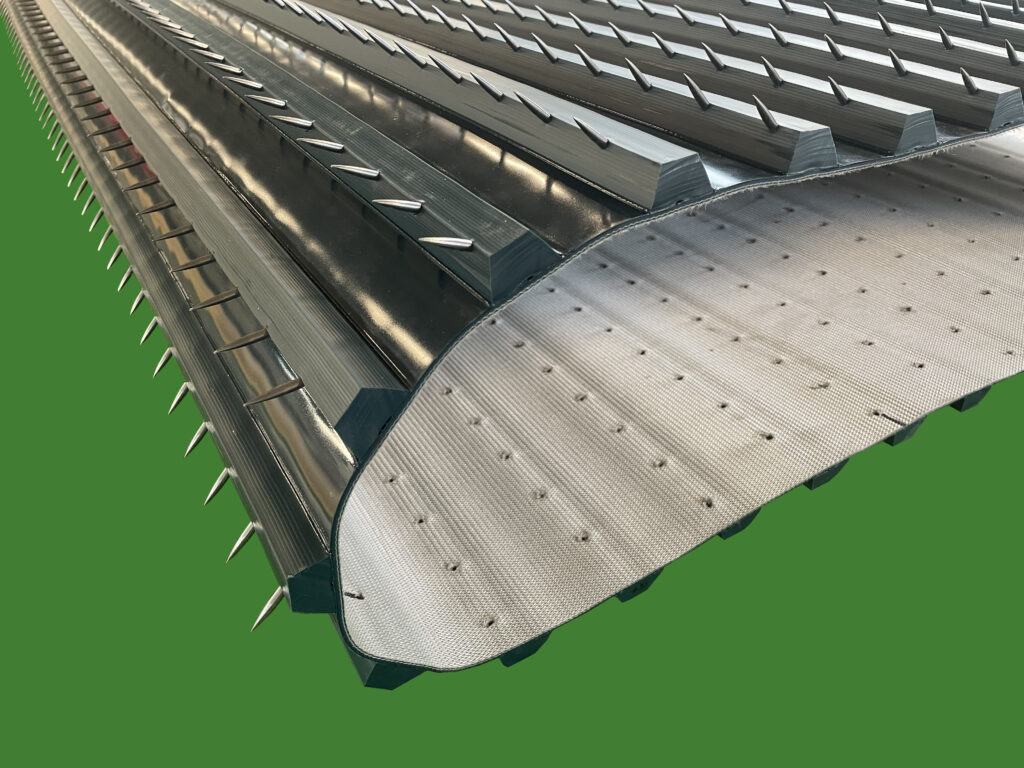

aluminium PAT5030

Application: Bale opener and hopper feeder for gross fibers

Advantages: Robust, stable laths and pins, smooth surface for easy maintenance

Profile of laths: 50mm wide x 30mm high with hollow core

Material of laths: Aluminium

Belt: Transilon belt

Endless connection: endless belt or overlapping belt connection

Pins: Standard 5,4mm diameter, lengths 53mm or 63mm

Support: Polyester web strips between laths

wood

Application: Bale opener, hopper feeder and mixing chambers

Advantage: different profiles manufactured internally available, ecologically

Profile of laths: different profiles depending on machine type

Material of laths: beech, ash or laminated wooden laths

Belt: Polychrom belt, transilon belt (in humid and wet production)

Endless connection: screwed overlapping connection, hook connector (simple mounting but wears out)

Pins: different sizes, optional with sherard-galvanization for oversea dispatch

Support: fabric or polyester support with cover ledges

PVC PKS3020

Application: hopper feeder and miling cutters

Advantage: robust, light-weight, geared drive on tooth belt

Profile of laths: 30mm wide x 20mm high with hollow core

Material of laths: PVC with wooden core and polyamid end caps

Belt: Transilon belt or tooth belt

Endless connection: overlapping connection

Pins: Standard 4x45mm or 4x55mm with pressing

Underlay: Polyester web strips between the laths possible

PE hygiene

Application: bale opener, hopper feeder, mixing chambers, miling cutter

Advantage: easy maintenance, chemical resistent, only plastic and metal components

Profile of laths: on application

Material of laths: Polyethylen (PE) white (natur) or black

Belt: Transilon belt or tooth belt

Endless connection: if required with a hinge connection

Pins: 2,95-4mm diameter, length between 38 to 64 mm

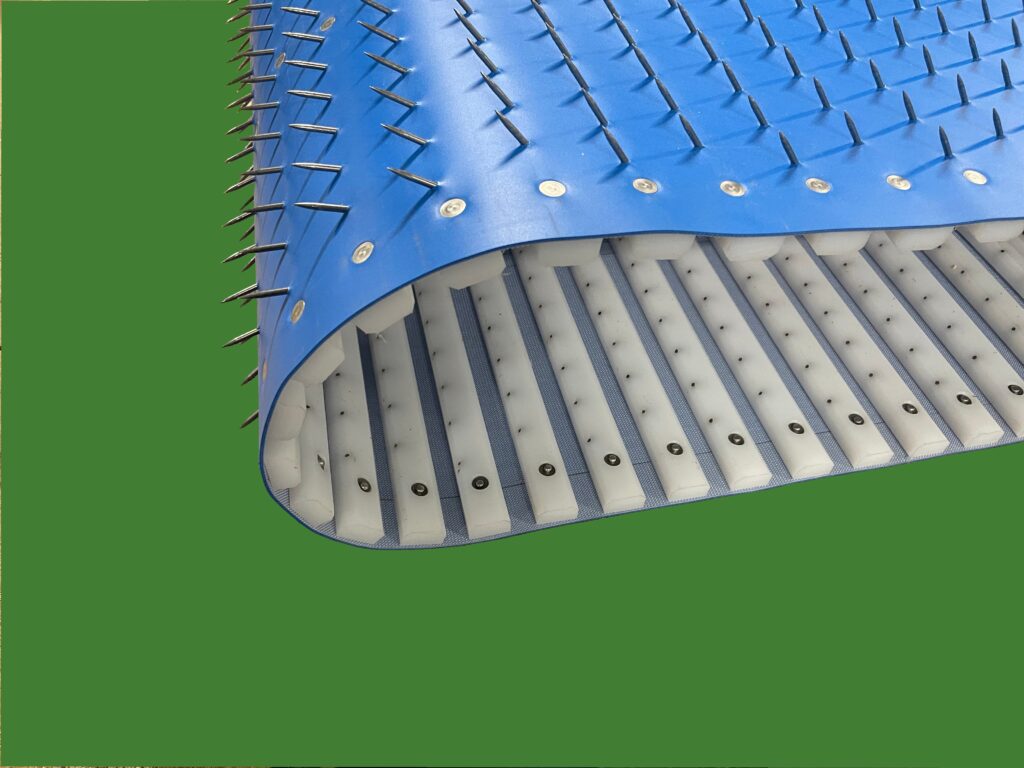

transilon spiked laths

Application: hopper feeder for long fibers

Advantage: robust, long durability, high sealing, chemical resistent

Profile of laths: different profiles depending on machine type and application

Material of laths: Beech or laminated beech depending on strain

Belt: None

Endless connection: if required with a hinge connection

Pins: 2,95-4mm diameter, length between 38 and 64mm

Characteristic: Laths are mounted below the transilon belt and pins are pushed through the belt. Special variants with wood or aluminium laths at the surface can also be manufactured.

Further spiked lattices

We produce further spiked lattices such as a transilon belt with rubber laths on top.