aluminium PAS5030

wood

PVC PKS3020

PE hygiene

We manufacture your lattice

Georg Koinzer GmbH & Co. KG has been manufacturing spiked lattices and lattices of high quality and different materials for the textile industry for over 70 years. We work together with all renowened original equipement manufacturers in the textile machine industry and produce on individual request for all textile and non-woven manufacturers worldwide. As a family-owned company we value long-lasting partnerships with our customers and we drive innovations and new solutions together. Our quality comes from our long experience in the field as well as our engaged employees, most of them are since decades with us.

We stand for product variety, quality and cooperation.

We are looking forward to your enquiry.

product variety

We offer spiked lattices and lattices out of different materials in different widths and lengths as well as spare parts.

quality

We manufacture high quality spiked lattices and lattices for the textile industry in Germany (Bebra, Hessen).

cooperation

We produce lattices for most OEMs of the textile machine industry. In addition to that, we deliver customized individual spare parts.

product portfolio

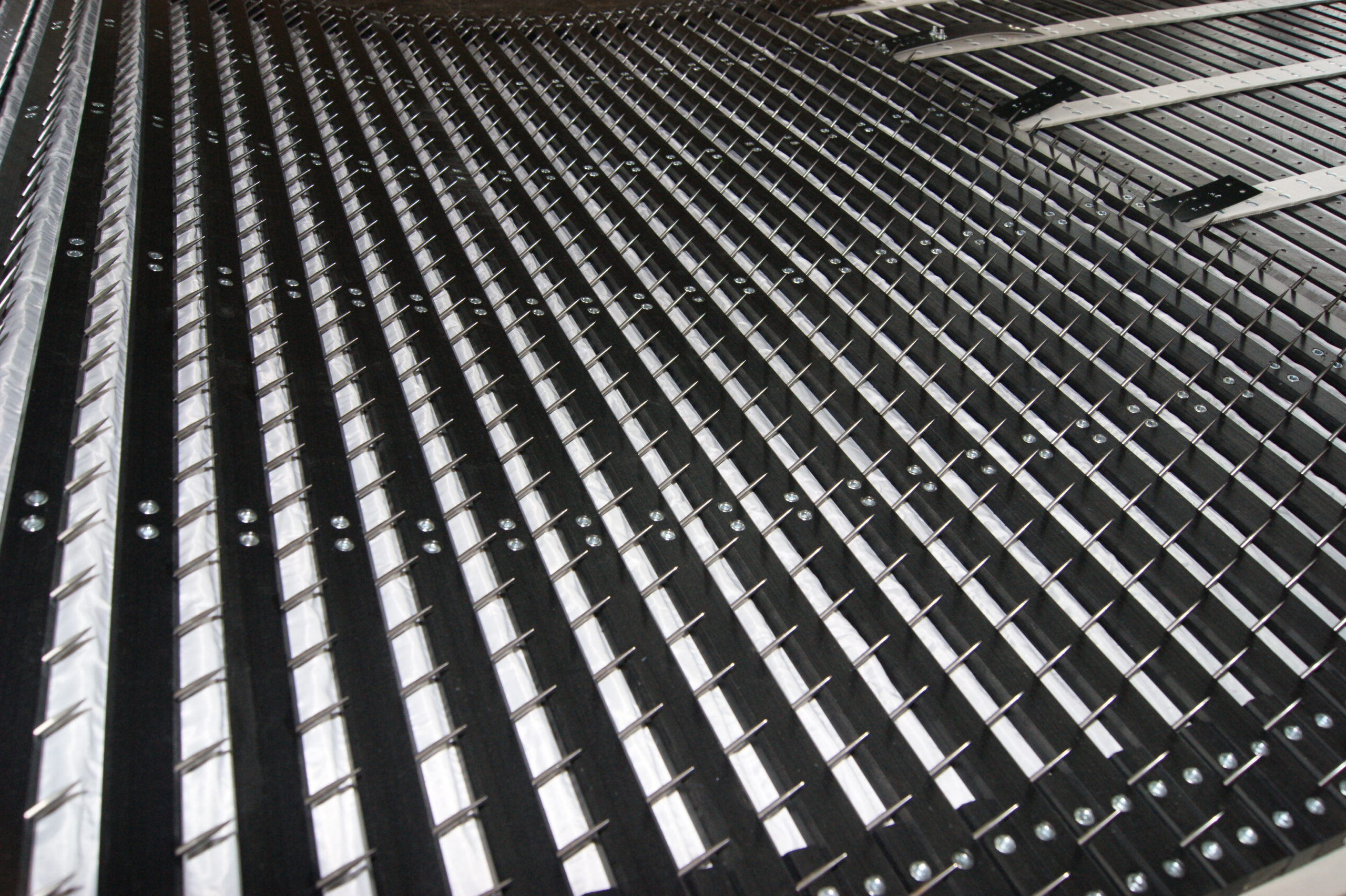

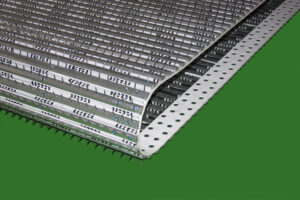

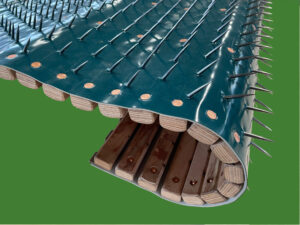

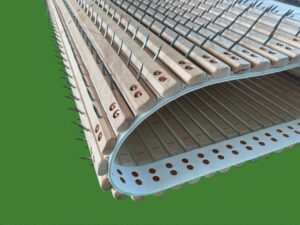

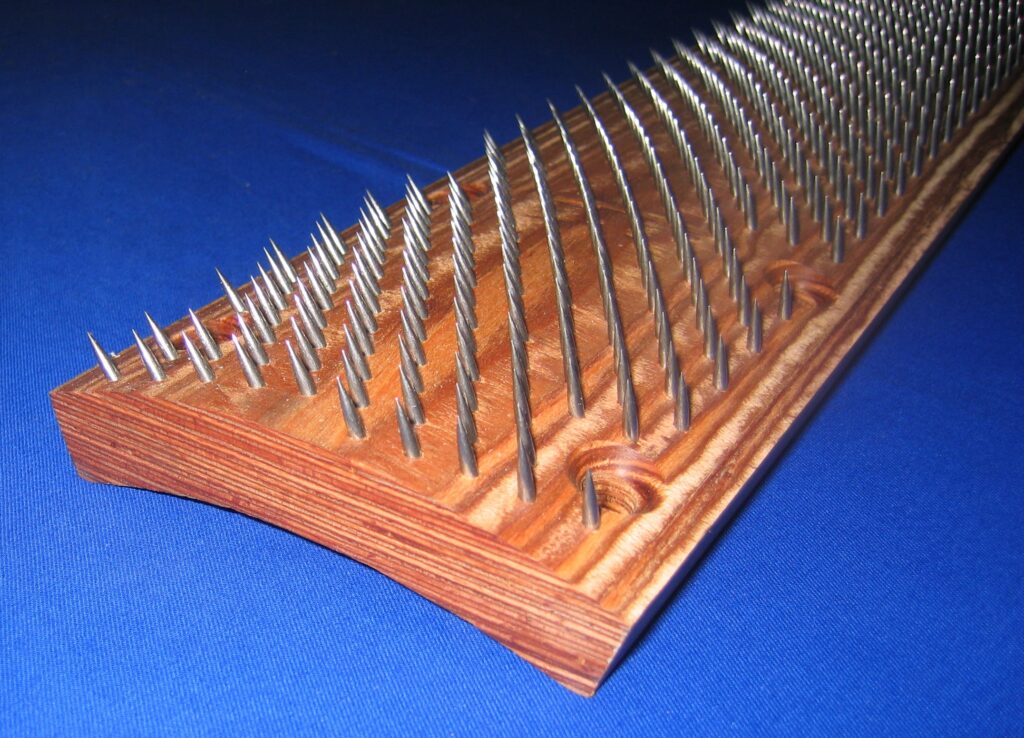

spiked lattices

We offer spiked lattices out of aluminum, plastic, wood and combined materials which are utilized in bale openers, hopper feeder and mixing chambers of all renowened textil machine manufacturers. Have a look at the advantages of each spiked lattice in order to find the best solution for your machine.

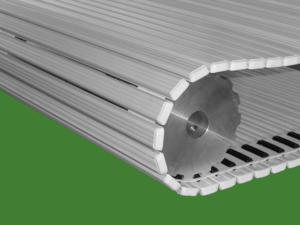

lattices

We offer conveyor lattices out of PE, PVC and wood. They are utilized in the textile industry for the horizontal and vertical transport of fibers, nonwovens and woven fabric. Have a look at the advantages of each material and the different options in order to find the best solution for your machine.

accessories

We offer accessories and spare parts like single spare laths, toothed belts and wheels, screws and bolts, endless connectors or backing-off laths for our (spiked) lattices.

spiked lags

The affiliated company tambula GmbH offers spiked lags for tambours made out of wood or aluminium for the textile industry. They are utilized in tearing and opening machines.

latest news

Outlook: Fairs in 2025

We will be exhibiting with our agency Symtech at IDEA in Miami (booth 2047) from 29.04.-01.05.2025 and with our agency NPK at Techtextil India in Mumbai from 19.-21.11.2025.

We would be delighted to welcome you to our booths.

25-years of employee anniversary

On 17.07.2023 we were happy to congratulate Markus Holzhauer for his 25-years employee anniversary at Koinzer. With great weather we could enjoy a bit of ice-cream in the sun to celebrate this event. Thank you Markus for your dedication to the company and the ice-cream 🙂

In September we could celebrate another 25-year employee anniversary. We are happy to have many employees with us with great knowledge and strong commitment.